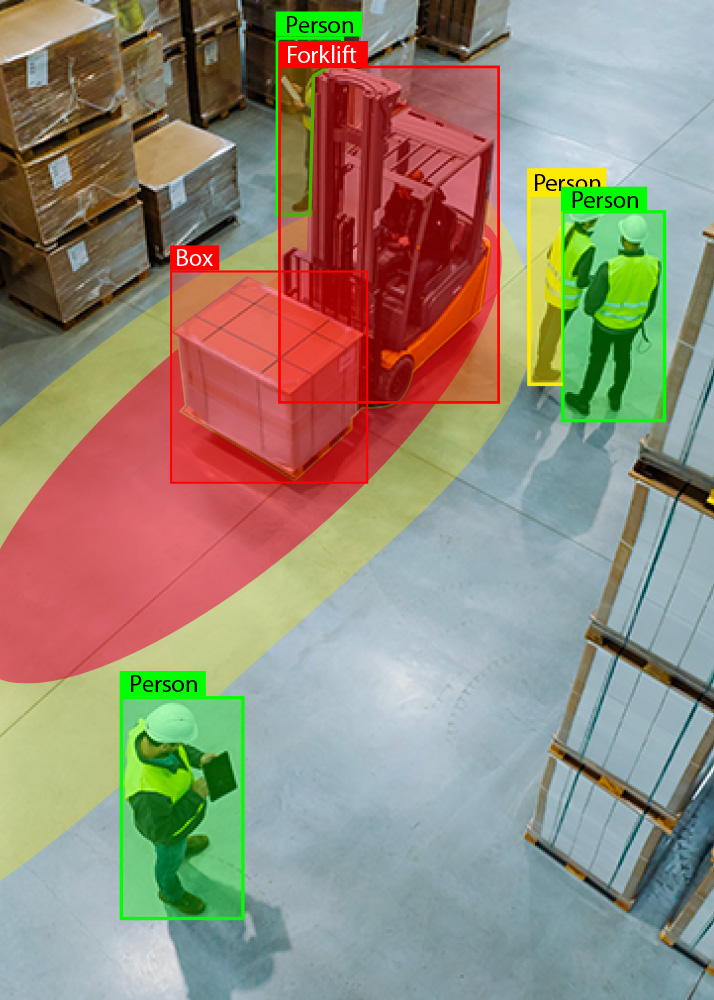

Maximize uptime, OEE and OLE in your facility by activating safety measures zone by zone, for any equipment. Protect your workforce and assets, minimize insurance claims by issuing alarms and alerts before the potentially dangerous behavior causes an accident. Define high-risk zones on a best-in class GUI. Monitor and proactively generate actions for high-risk events before they become problems.

SOHO accepts streams from any combinations of camera, LIDAR or wireless sensor data to continuously locate people, equipment, or vehicles in 3 dimensions within critical areas, indoor and outdoor, to predict the upcoming hazard, before it becomes a catastrophic event. SOHO is your time machine, transforming any detected risk into an actionable information or a proactive response by instantly halting equipment and machinery, triggering alarms, and displaying warnings to prevent accidents and unauthorized access.

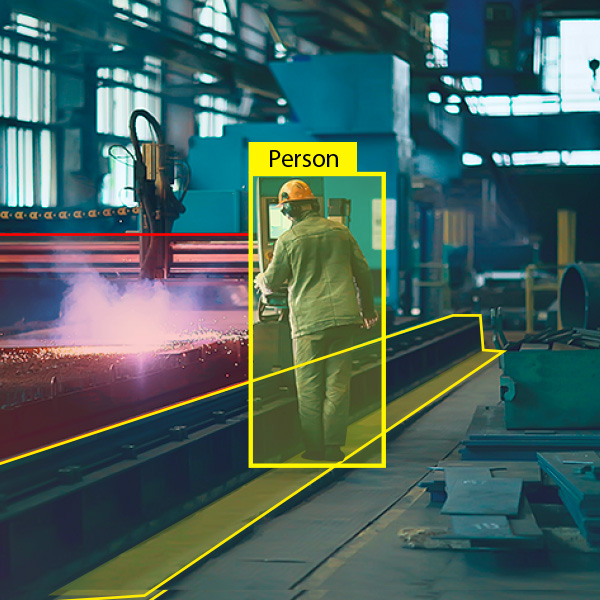

SOHO protects workers around heavy machinery. By monitoring safety zones, the system detects when a worker enters a restricted area, automatically halting machinery to reduce accident risks. This proactive safety solution provides peace of mind in high-risk environments, ensuring safe operations and compliance with industry standards. Reliable, adaptable, and efficient, SOHO is a visibility tool for workplace safety and security across commercial and industrial applications.

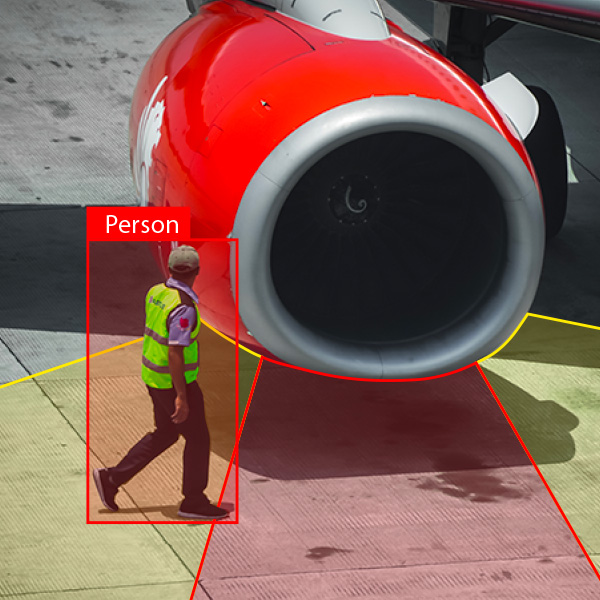

Transform danger zones into safety zones using cameras, LIDARs or wireless sensors. Gain visibility over risky behavior, capture records and establish metrics. Use the records or risky behavior to train staff, establishing a culture of accountability.

SOHO enables data-centric and facts-based safety protocols in operations, providing a tool for the operations executives to analyze and quantify safety metrics and create a safety culture, by targeted and relevant training, and establish records of risky events for future risk mitigation.

SOHO autonomously monitors and facilitates response of your choice to safety events. The captured records provide visibility into leading hazard indicators from a single workstation to zones, departments and across facilities, scaling with your operation.

Setup is as easy as 1-2-3

SOHO Auto-Detects Cameras, LIDARs, Wireless Sensors during plug-and-play installation. Leverage existing POE camera infrastructure that is in place without the need for costly re-wiring or installations.

Establish connections from cameras and sensors to a local edge CPU or server that runs SOHO. Securely process data on-premise with low latency, without the need of persistent cloud connectivity, and at the same time preserving anonymity.

Transform information into actions by adding the zones of interest using the GUI, decide on actions to be taken and connect the outputs of the SOHO system to industrial automation layers to start or stop heavy equipment, enable or disable access, and activate alarms.

SOHO safety system easily scales for deployments as it integrates with existing camera systems. This compatibility makes deployments easy by adding safety zones to the existing camera views and utilizing the existing infrastructure without the need for costly wiring, camera replacements or upgrades. Enhance your safety measures efficiently by leveraging the equipment you already have in place.

SOHO EHS system offers upstream connections for monitoring and controls through a mobile application or a browser interface, a locally managed server provides open API access to other automation layers. Whether you need offline operation for local management and anonymity or prefer optional cloud-based access to control the system from anywhere, we've got you covered. Open APIs enable seamless integration into software packages such as IMS, MES, WMS, allowing you to monitor and manage safety protocols according to your specific needs.

All device connectivity is through ethernet or POE connections. SOHO is compatible with industrial communication standards and interfaces such as MODBUS on RS485, IO-Link, and others. Contact us for further information for deployment options.

Proactively alert the workforce in the risk zones around the heavy equipment.

Stop the equipment if someone crosses the danger zone perimeter.

The trick is to prevent a moment of distraction from being the trigger of an accident.

Keep the workers and the passengers safe and moving. Eliminate downtime and reportable incidences to a minimum and keep all the crew safe, have all passengers arrive at their destination safe, secure and on time. Keep the OEE and uptime metrics maximized.

Keep those who feed us safe, machines working and businesses thriving. One of the most common issues around heavy agricultural equipment is loose clothing, reaching into machines and simply not paying attention to the surroundings. Proactively monitor the harvest operations by the cameras and lidars mounted on the equipment and issue simple alerts like a horn for warning or stop the vehicle for dangerous situations, eliminating accidents.

Set your warning zones for alerts and danger zones for actions to keep your crew safe at work.

Keep what matters the most safe, keep operations rolling forward and schedules on track.

Enhance safety in hallways, staircases and within zones where medical care patients and caregivers can slip and fall.

We are all on a schedule and in constant hurry. Premature truck departure while being sideloaded is a common hazard in loading and unloading operations.

Automate your logistics facility, or your distribution warehouse where the truck rolls are managed by an always-on monitoring and control system.

Manage gates and monitor chocks relative to the status of the loading or unloading operations performed by forklifts.